Advanced Therapy Medicinal Product Technology Development Center

One of the new concepts that emerged with the increasing development of medical science and biological knowledge is “regenerative medicine,” known as the future medicine.

In the 20 years, the concept of regenerative medicine has entered the medical field and has become one of the favorite fields for research centers and biotechnology and pharmaceutical companies.

Regenerative medicine tries to find new ways to prevent, diagnose and treat diseases in order to move from traditional medicine, which works around the diagnosis and treatment with chemical drugs and to some extent biotechnology, to personalized medicine and precision medicine, for which Biological products will play an important role.

Therefore, Advanced Therapy Medicinal Products (ATMPs) are defined. ATMPs are therapeutic products based on genes, tissues, and cells that are used in humans. Accordingly, ATMP’s products are divided into four different groups, which are:

In the 20 years, the concept of regenerative medicine has entered the medical field and has become one of the favorite fields for research centers and biotechnology and pharmaceutical companies.

Regenerative medicine tries to find new ways to prevent, diagnose and treat diseases in order to move from traditional medicine, which works around the diagnosis and treatment with chemical drugs and to some extent biotechnology, to personalized medicine and precision medicine, for which Biological products will play an important role.

Therefore, Advanced Therapy Medicinal Products (ATMPs) are defined. ATMPs are therapeutic products based on genes, tissues, and cells that are used in humans. Accordingly, ATMP’s products are divided into four different groups, which are:

- Gene therapy drugs

- Cell therapy drugs

- Tissue engineering drugs

- Combination drugs

ATMP Center:

Royan ATMP-TDC was established in 2018. This center’s mission is to create a safe and efficient bridge between the laboratory and preclinical stages of developing regenerative medicine products and reaching the useful biological medicine to produce on a large scale in the industry. Therefore, this center has created a robust scientific infrastructure for developing products based on regenerative medicine after selecting the product from among the research projects with suitable conditions in Royan Research Institute and designs and executes in standard space.

ATMP center perspective:

- Development of advanced cell-based medical products in the field of orthopedic, skin, degenerative, autoimmune, eye, neurological, and metabolic diseases, etc.

- Set up a reference laboratory to control the quality of cells and related products and become the certified laboratory of the Food and Drug Administration.

- Development of accurate and reliable standards for the production and quality assurance of products based on regenerative medicine.

- Exporting new products based on regenerative medicine to neighboring countries to strengthen the knowledge-based economy.

- Achieving the country’s and the region’s top rank in the development, production, and export of advanced cell-based medical products in the field of regenerative medicine during the next decade.

ATMP Center’s Units:

- Production Unit:

The production unit is equipped with two grade B clean areas on two floors with a total area of approximately 335 square meters equipped with specialized equipment for mass production and cell culture.

- Quality Control Unit:

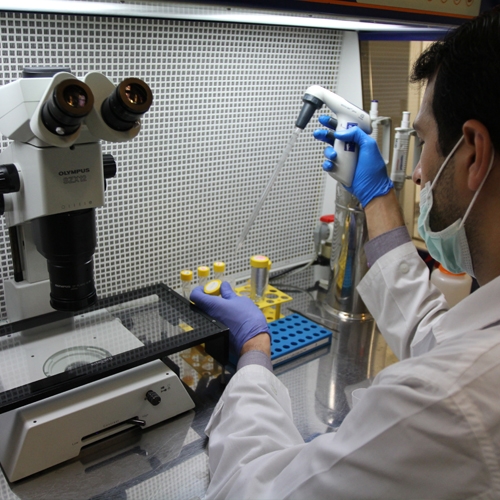

The comprehensive quality control unit is ready to provide the highest quality services by using specialized people aiming for optimal and non-exclusive advanced equipment usage. This unit’s purpose is sampling, testing, using a test validation program, and doing extensive documentation under standard guidelines. The quality control unit consists of four laboratories, including molecular, microbial, flow cytometry, and advanced imaging, which provide specialized services in line with the center’s goals and programs.

- Quality Assurance Unit:

The quality assurance unit is responsible for the design, deployment, management, maintenance, and improvement of the “Quality Assurance System” in compliance with GMP requirements to ensure product quality from the infrastructure and material supply to the consumer. This unit ensures that the product conforms to the expected quality of standards and national and international regulatory bodies by monitoring the accuracy of performance in each GMP’s requirements.

- Technical and Engineering Unit:

This center is equipped with specialized, up-to-date, and reliable devices and equipment for producing efficient and effective products, as well as their accurate and correct analysis to provide high quality and reliable products for patients. Maintaining the quality factors continuously with the least fluctuation and maintaining the product specifications is one of GMP requirements. Therefore, up-to-date and valid equipment is essential in this center to maintain continuity and repeatability of product quality results. The main equipment required for production processes is mainly separate for each product, and all equipment is used in a validated manner.

- Clinical Trial Unit:

The clinical trials unit manages and coordinates the ongoing clinical trials at the Royan ATMP Center.

The products that are being developed and produced in this center include the following:

1- Mesenchymal stem cells (ChymiaCell)

Stem cell production with international standards for use in clinics is one of the world’s new technologies. Along with leading countries in this field such as the United States, Australia, and Japan, Iran is developing cell therapy and producing the required cells under GMP standards and has made significant progress in this field. Iran is the first country among the neighboring countries that have developed such products.

Iran vs. other countries

There are similar products globally; their most important is the product of Mesoblast Company. Mesoblast is one of the largest and most reputable regenerative medicine companies founded in 2004 in Australia.

ChymiaCell is of particular importance due to its unique proliferation and differentiation characteristics, in addition to achieving a homogeneous population. This product is also produced at one-tenth of the cost of similar foreign products, which will lead to significant currency savings.

Application of Mesenchymal Stem Cells:

Mesenchymal stem cells have been used in various diseases, including osteoarthritis, rheumatoid arthritis, and chronic low back pain, with good therapeutic results. In this center, these cells will be used to treat osteoarthritis and chronic low back pain.

- Technical Specifications of Chymiacell:

Chymiacell is a 15 ml frozen cell suspension containing (75 ± 5) × 106 clonal stromal mesenchymal cells isolated from a healthy and qualified donor’s bone marrow. In the final product formulation, these cells are frozen and stored as a cell suspension in excipients (product storage solution or final product freezing medium) in a 25 ml freezing bag (pre-packaged) and stored in the vapor phase of a liquid nitrogen tank.

2- Keratinocyte sheet

Application: Treatment of burns

Burns is one of the most painful and bitter experiences a person can have in life because, in addition to causing much pain, they can leave a scar even after healing. Burns is one of the most common types of injuries in Iran.

Iran vs. other countries

Engineered skin products were the first tissue engineering products on the market. One of the well-known companies in this field is Tego Science Company, which was established in Korea in 2001 and produces skin cell therapy products that originate from human epithelial cells. The Royan ATMP Center’s final product is technically similar to Kaloderm (the third allogeneic cell therapy product in the world) for wound healing. This product costs $ 265 for a 10 cm2 sheet, while the average product required for the treatment of burns is 200 cm2, which has a high cost for the patient. With this product’s mass production in the Royan ATMP center, it is hoped that it will be available for patients in the country and even neighboring countries at a much lower price.

Technical Specifications:

The keratinocyte epithelial sheet is a skin replacement derived from foreskin epidermal tissue. This sheet has features such as safety for human applications, effectiveness in treatment, and application and handling suitability. This sheet also prevents heat and fluid loss and reduces the amount of infection, inflammation, and pain at the site of burns and wounds.

keratinocyte sheet

3- Bilayer skin

Application: Treatment of diabetic wounds

Diabetes, the most massive epidemic of the century, is currently the fastest-growing. People with diabetes are prone to many long-term complications due to high blood sugar, including diabetic feet. Neuropathy is one of the main problems in people with diabetes. Following neuropathy, people with diabetes do not feel the sores on their legs, so the injury can progress and even cause infection. On the other hand, reduced blood flow can cause pain, infection, and reduced wound healing. Severe infection can sometimes lead to deformities of the legs and eventually amputation. Common treatments for diabetic foot ulcers include:

1- Medication, which mostly includes antibiotics and painkillers.

2- Topical treatments such as dressings containing silver or silver sulfadiazine creams, gel or solution of polyhexamethylene biguanide (PHMB), iodine, and medical honey in the form of ointment or gel, and

3- Surgery-based treatments that reduce pressure and infection around the wound.

Despite available treatments, one amputation in diabetics patients occurs every 5 minutes in the world. Diabetes is relatively prevalent in Iran (in 1.5 million people), to which 200,000 people are added every year, and 5% of diabetics in Iran are suffer from amputation. Therefore, new methods have been introduced to treat diabetic wounds, in which engineered skins are used to cover the wound surface to shorten the healing time.

In the current project, using tissue engineering technology, two types of keratinocytes and fibroblasts are implanted on the surface of collagen gel, and a two-layer skin is obtained.

Iran vs. other countries

Engineered skin products are among the first tissue engineering products on the market. One of the leading companies in this field is the American company, Organogenesis, established in 1985 to strengthen the capacity for healing through the development, production, and selling of wound care products on the medical and surgical markets. One of the famous products of this company is double-layer skin with the brand name “Apligraft.” The price of each unit is $ 1000-1200.

The final product of Royan ATMP Center is entirely similar to Apligraft in terms of technical specifications. Mass production will lead to a lower price and eventually be used for diabetics in the country and even neighboring countries.

Technical Specifications:

It is derived from fibroblasts cultured in the type 1 collagen matrix, and then keratinocytes are located on the fibroblasts to form a bilayer skin replacement. This product is more effective than similar skin products due to its live cells.

By producing large amounts of cytokines and growth factors, this product enables differentiation and proliferation in chronic and incurable wound beds, and these wounds heal faster and are less prone to fibrosis. This ability may be due to fibroblasts and keratinocytes derived from the baby’s skin, which could better stimulate wound healing because they are young.

Bilayer skin

The global market of regenerative medicine’s products

It is expected that regenerative medicine has a significant effect on health care for expensive, specific, and chronic diseases (such as cardiovascular disease, stroke, diabetes, neurological diseases such as ALS, Parkinson’s, and Alzheimer’s), which currently embrace significant health and treatment cost.

Previously, it was supposed that the market for regenerative medicine would be 8.8 billion dollars until 2016; but this market reached 18.9 billion dollars, and in 2018, 13.8 billion dollars growth (73% of 2017) was observed. Now, the market for regenerative medicine is projected to grow by 20.3% (53.7 billion$) annually by 2021, to 170 billion$ by 2030, and Increase to 530 billion$ by 2050. Economically, the annual growth rate (CAGR) of this industry, from 2010 to 2015, has been announced at 24%, making this area very attractive for large pharmaceutical companies to invest in.

Despite the significant annual growth in the reconstructive medicine industry, one of the economic problems facing companies is the high R&D intensity index in this area.

This index represents the percentage of the company’s annual profit spent on research and development of new products in the company. It has been shown that companies operating in the field of reconstructive medicine spend an average of 21% of their annual profits in the R&D unit on research and development of new products, which is one of the major challenges for economic investors in this field.

Accordingly, the ATMP center needs strong financial support to improve and achieve the product to be released.

On the other hand, the EISA International Exhibition has been created to introduce knowledge-based products to national and international investors. This exhibition will provide the opportunity to introduce our products to the international community and will create the possibility of cooperation between investors.